The duvets undergo a total of 15 test parameters to assess and measure the following main aspects:

- The amount of down

- The quality of down

- Thermal insulation

- Breathability

- Particle density

- Quality of the fabric

- Construction quality

The amount of down

To measure the proportion of down, the duvet's filling is taken out and weighed. The amount of down and other content in the filling is then analyzed. The percentage of down must agree with what is declared on the product.

The quality of down

The quality of the down is determined, among other things, by the weight of the down, which is measured in terms of the volume in cubic centimeters that one gram of down gives under a certain pressure. The higher the volume, the better the load capacity.

The purity of the down from bacteria is assessed by measuring the content of oxygen in the down. The oxygen itself does not necessarily mean bacteria but indicates a higher content of organic residues which in turn can give rise to bacteria. The limit for approval in Europe is 10 mg per 100 g, which all blankets passed by a good margin. The cleanliness of the down from dust is also measured by soaking the down and measuring the turbidity of the water.

Fragments of damaged down or damaged feathers and foreign material that does not contribute to the down's load-bearing capacity or heat-insulating ability are classified as other contents. This must not exceed 5 percent of the total filling if the quilt is to meet the highest quality level (Class 1).

Thermal insulation

The blanket's ability to retain heat naturally depends on the amount of down, but also on the quality of the down. A higher carrying capacity (see quality above) means that the down can hold more insulating air. The insulating ability is assessed by measuring how well the heat in a body is maintained by the blanket's insulating ability. The measured value is given in the unit Clo (Clothing insulation) where the value 1 corresponds to the heat insulation required for a person to maintain the body temperature at 21°C.

Breathability

The blanket's ability to breathe (ventilate moisture from the body) is assessed by measuring the amount of vapor that is allowed to pass through the blanket during a certain time interval. The higher the vapor permeability, the better the breathability.

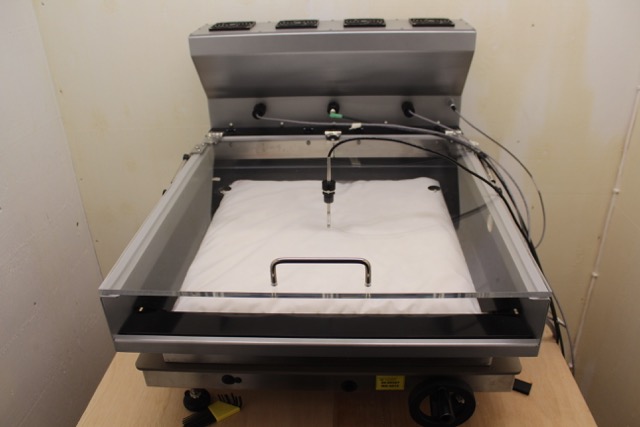

Particle density

Allergenic particles from the down can cause allergies in sensitive people, and it is therefore important that the textiles around the down are tight. To test the particle density, the blanket is rotated in a drum for 30 minutes, while being subjected to blows with rubber blocks. The number of leaked particles is measured and in order to meet the laboratory's "Downproof" tightness requirements, the textiles must not let more than a certain amount of particles through. Based on the number of leaked particles, the laboratory grades the blankets on a 5-point scale, with 5 being the best.

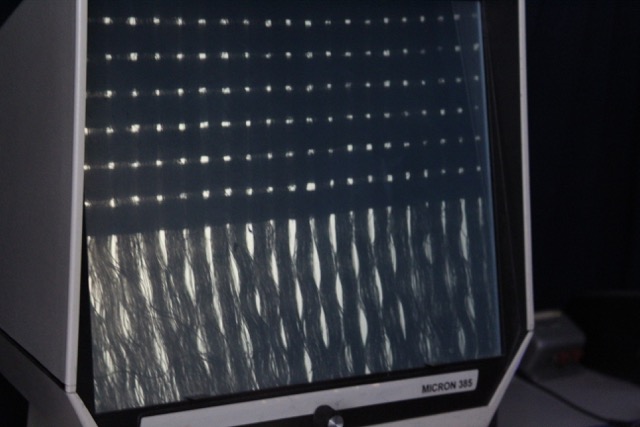

The quality of the fabric

is determined, among other things, by the thread density. The more threads per square inch (in2) the better. In the test, the laboratory has also assessed the general textile quality (possible manufacturing defects).

Construction quality

Construction quality includes the distribution of the down in the quilt, the quality of the seams and a general assessment of the construction quality. The assessment is made on a 5-point scale, where 5 is very good.

Grading and weighting of the results

The results from the various parts of the test are graded on a scale from 1 to 10, where 10 is the best.

The grades for the various parts of the test are weighted together to form a total grade as follows:

- The amount of down and the quality of the down: 40%

- Thermal insulation and breathability: 40%

- Particle density and the quality of fabric: 10%

- Construction quality: 10%