How we test - Vacuum cleaners

The laboratory tests of vacuum cleaners are carried out by SLG GmbH in German Hartmannsdorf, accredited for testing vacuum cleaners. The tests are based on well-established standards and the laboratory's in-house methods.

The laboratory tests include the following parts:

A. Technical characteristics

B. Battery capacity (if cordless)

C. Removal of dust on hard floors

D. Cleaning capacity of larger particles hard floor

E. Removal of dust on carpet

F. Removal of longer fibers and hair on textiles

G. Cleaning along walls

H. Sound level

I. Filtration efficiency

J. Maneuverability when vacuuming

K. Ease of emptying container/ change bag

L. Manageability storage

The test is based on the international standard IEC 62885-2 for vacuum cleaners.

A. Technical characteristics

The technical characteristics of the vacuum cleaners such as power, weight, cord length and so on are documented by the laboratory.

B. Battery capacity (if cordless)

The battery on each model is conditioned (discharged and recharged 3 times) first before each test to extract maximum capacity. The vacuum cleaner is run at maximum power on a hard floor according to the specifications in the standard. The battery capacity is measured and the time noted at 90% and 40% of remaining suction power.

C. Removal of dust on hard floors

A certain amount of dust is distributed on a surface according to the specifications in the standard. The vacuum cleaner is run at maximum power to suck up the dust with the standard nozzle in a forward and backward motion. The percentage of dust absorbed is determined by weighing the remaining dust on the surface. The result is reported as % absorbed dust.

D. Cleaning capacity of larger particles hard floor

A certain number of lentils or rice grains are distributed on a surface according to the specifications in the standard. The vacuum cleaner is run at maximum power to suck up the particles with the standard nozzle in a forward and backward motion. The number of particles absorbed is determined by counting the remaining particles on the surface. The result is reported as % absorbed particles.

E. Removal of dust on carpet

A certain amount of dust is distributed on the surface of a carpet according to the specifications in the standard. The vacuum cleaner is run at maximum power to suck up the dust with the standard nozzle in a forward and backward motion. The percentage of dust absorbed is determined by weighing the remaining dust on the carpet. The result is reported as % absorbed dust.

F. Removal of longer fibers and hair on textiles

A certain amount of fibers (hairs and threads) is distributed on a surface according to the specifications of the standard. The vacuum cleaner nozzle (furniture nozzle) is moved back and forth, at maximum power, over the entire surface in a specific pattern until all fibers are sucked up. The nozzle is then cleaned of the fibers. The time it takes to suck up all the fibers and clean the nozzle is noted.

G. Cleaning along walls

A fixed amount of dust is distributed on a carpet along one wall and one corner according to the specifications in the standard. The vacuum cleaner is driven in a forward motion along the wall up to the corner with the standard nozzle at maximum power. The distance between the wall (side and straight ahead) where the vacuum cleaner has not managed to suck up the dust is measured.

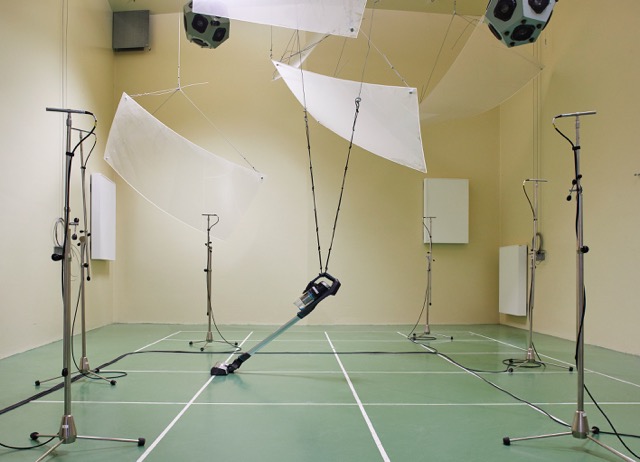

H. Sound level

The vacuum cleaner is placed on a hard floor in a so-called reverberation room, intended for measuring the sound power level according to the specifications in the standard. The measurement is made at maximum power.

I. Filtration efficiency

The number of particles that the vacuum cleaner's filter does not filter out is measured.

J. Maneuverability when vacuuming

Assessment of the power required and how easy it is to maneuver the nozzle when vacuuming on carpet, hard floors and under lower furniture at maximum power.

K. Ease of emptying container/ change bag

Assessment of manageability and hygiene when changing the vacuum cleaner bag/ emptying the dust container.

L. Manageability storage

Assessment of how much space the vacuum cleaner takes up during storage, the coiling function of the power cord and storage of nozzles and any hose.

Interpretation and grading

The results of the test are interpreted and graded in consultation with the laboratory. The grades are set on a 10-point scale, where 10 is the best. Grades below 6 are only given if the results can be considered bad or significantly worse compared to other products in a comparative test.

The ratings for the various sub-moments are added together to form a total rating with the following weight (vacuum cleaner with cord and bag):

Cleaning performance (C, D, E, F, G): 60%

Noise level and filtering of particles (H, I): 25%

Manageability (J, K, L): 15%

Criteria for Testfakta's quality label

Best in test

In a comparative test with the aim of identifying a test-winning product, a representative selection of comparable vacuum cleaners for a specific market is tested. The product that performs best overall (highest overall rating) is crowned as "Best in test".

Verified Quality & Performance

In a verification test, the customer's vacuum cleaner is tested against some selected, comparable reference products. Interpretation and grading of the test results follow the same guidelines as above. To qualify for Testfakta Quality & Performance, it is required that the vacuum cleaner performs consistently well, with a total rating of at least 8.0 (+/- 2.5%) and no partial rating below 6.0 (+/- 2.5%).